In industrial vacuum cleaners, length may refer to the length of the vacuum pipeline and other components. Theoretically, the length of the pipeline affects the airflow. For example, a longer pipeline increases the resistance path for airflow. According to fluid mechanics principles, air flowing through a pipeline experiences friction with the pipe walls; the longer the pipeline, the greater the friction loss. This can lead to a reduction in airflow because as friction loss increases, the energy driving the airflow is consumed, reducing the amount of air that can reach the vacuum inlet. For instance, in a large industrial facility, if the pipeline length from the vacuum cleaner main unit to the farthest vacuum point exceeds the reasonable design range, even if the vacuum pump has sufficient power, the airflow reaching the working area may not meet the effective vacuuming requirements.

Wind pressure reflects the pressure condition of air flowing through the system. For industrial vacuum cleaners, increasing the pipeline length affects wind pressure. On one hand, a longer pipeline increases the along-the-way resistance of air in the pipeline, similar to how water pressure gradually decreases as water flows through a long pipe. The friction loss in a long pipeline causes a gradual decrease in pressure, meaning wind pressure decreases. For example, in ventilation and dust removal systems, if the total pipeline length is long and no reasonable compensation for wind pressure is made in the design, the suction power in the subsequent sections may significantly weaken, affecting the vacuuming effect. On the other hand, longer pipelines may also cause changes in local resistance, such as bends and joints in the pipeline, which have a greater cumulative impact on wind pressure changes over long distances, increasing the total pressure loss and reducing effective wind pressure.

Airflow, wind pressure, and pressure loss are interrelated. From a power perspective, the fan provides energy to generate wind pressure to drive air to form airflow. In this process, if there is significant pressure loss, such as due to excessively long pipelines or unreasonable pipeline layouts, the fan needs to output more power to maintain a certain airflow and wind pressure. There is a specific relationship between wind pressure and airflow; when the fan speed remains constant, a decrease in airflow due to pipeline factors may cause an increase in wind pressure, but it will not increase indefinitely as they are also limited by the fan performance curve. Meanwhile, pressure loss is an indicator of energy loss in this process, affecting the efficiency of the vacuum system and determining the selection of the fan and the size of the pipeline. If the pressure loss is too high, vacuuming efficiency decreases, potentially leading to insufficient suction power and ineffective removal of dust and debris.

2.1.1 High-Efficiency Filtration

Waidr industrial vacuum cleaners excel in filtration. They use imported Japanese Toray coated filter elements and high-efficiency HEPA filters. These high-quality filters can effectively filter out fine dust particles. For example, in textile factories with lint, fibers, and other fine pollutants, these vacuum cleaners can capture these tiny substances, ensuring relatively clean discharged air. This also prevents fine dust from entering the vacuum cleaner and damaging machine components, extending equipment life, protecting the fan, and improving overall vacuuming efficiency. Especially in electronics factories with high cleanliness requirements, this filtration function is advantageous, providing good air quality assurance for the production environment.

2.1.2 Reduced Clogging and Easy Cleaning

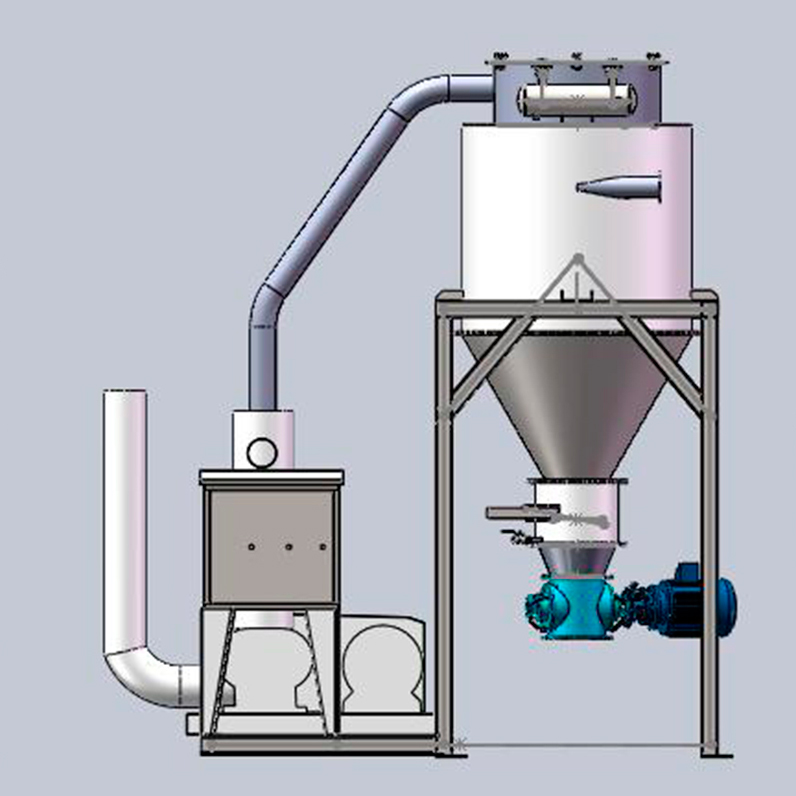

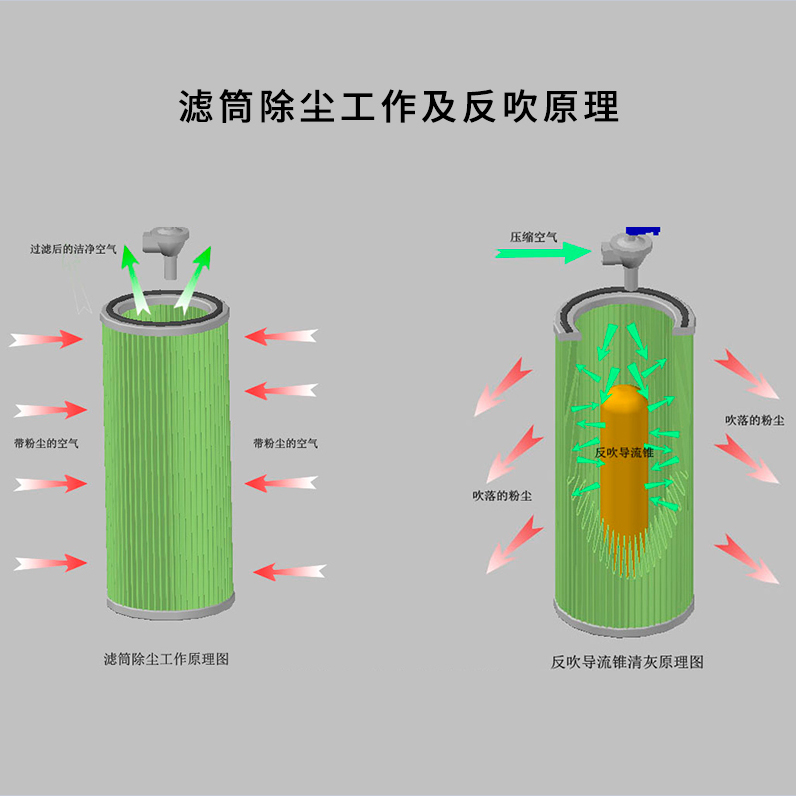

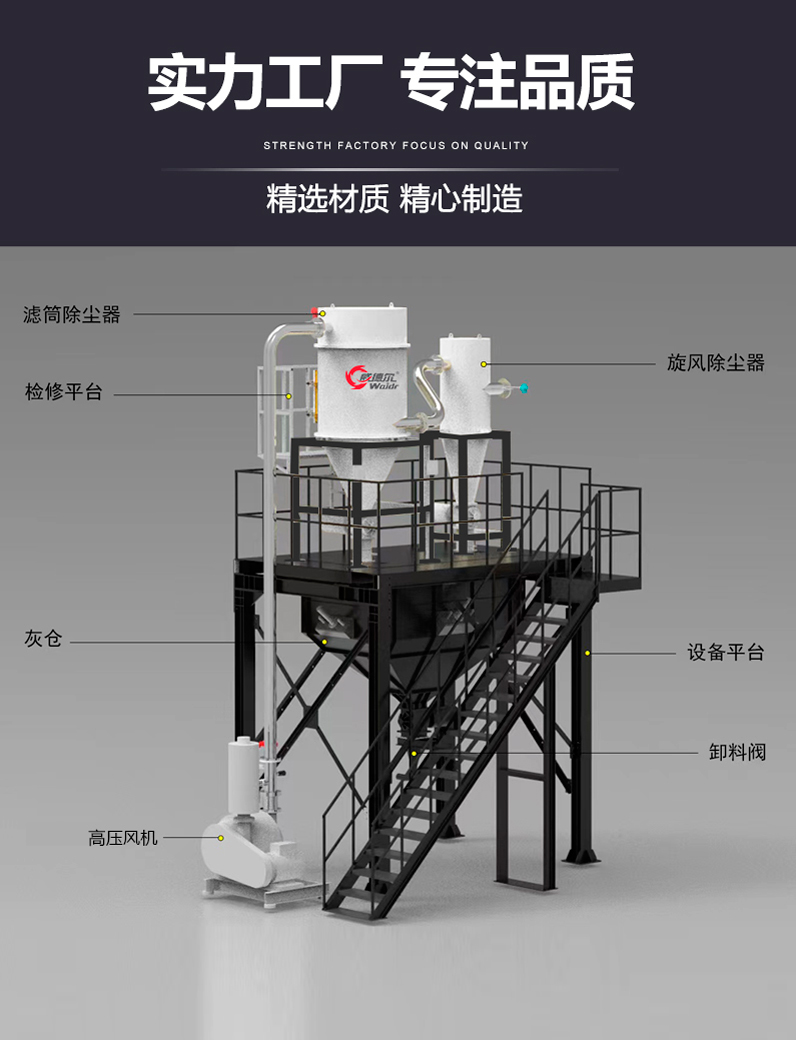

Many Waidr vacuum cleaner models use side suction ports combined with cyclone separators, effectively reducing the likelihood of filter clogging. For example, when handling conditions with many solid particles (such as iron filings, sand, etc.), the cyclone separator can preliminarily separate larger particles and dust through centrifugal force before they reach the filter, reducing the filter's burden. Additionally, independent pulse control valves perform automatic backflushing for dust removal. In factory environments with long continuous working hours or high dust concentrations, this ensures continuous vacuuming while periodically cleaning the filter cartridge, keeping the equipment in good working condition. The operation is simple, saving manual cleaning time and avoiding secondary pollution during manual cleaning. In some Waidr models (such as those handling conditions with a lot of dust), filter cleaning can be done while the machine is running, such as by manually shaking the dust rod to clean the filter, simplifying maintenance procedures.

2.2.1 Customized Power Source and Adaptability

Waidr vacuum cleaners use specially customized aluminum casting processes for their power sources. This process has many advantages, such as addressing thermal expansion and contraction issues due to regional temperature differences, preventing vacuum cleaner failures caused by temperature changes, and improving equipment stability and adaptability. Whether in cold northern winter workshops or hot southern summer workshops, they can operate stably. The use of brushless high-pressure fans provides strong suction power. For example, in grinding workshops to remove metal shavings or in woodworking workshops to remove sawdust, the strong suction provided by brushless high-pressure fans can effectively clean various debris. They can also work continuously without stopping, significantly improving cleaning efficiency in industrial production scenarios and reducing downtime maintenance costs and production interruption risks.

2.2.2 Overload and Other Protection Mechanisms

Waidr control systems use Schneider control panels with functions such as overheating, overload, and phase loss protection. In some industrial scenarios, if the vacuum cleaner works continuously for long periods or under unstable power supply conditions, these protection functions can prevent damage to the vacuum cleaner due to excessive current, high temperatures, or phase loss. This reduces equipment maintenance costs and extends equipment life. The control panel can also customize control of dust removal equipment and pulse valves, allowing for personalized settings and adjustments based on different working environments and vacuuming needs, improving equipment adaptability and work efficiency.

2.3.1 Safety Assurance

Whole-machine grounding is an important design feature of Waidr vacuum cleaners to ensure safe use. In industrial environments with potential electrical fault risks, if the equipment leaks electricity, whole-machine grounding can safely direct the current into the ground, preventing operator electric shock and ensuring personal safety. The standard thickened wear-resistant anti-static hose is both wear-resistant and prevents safety hazards caused by static electricity. For example, in chemical workshops or conditions with flammable and explosive dust, the anti-static function is particularly important, preventing serious accidents such as explosions and fires caused by static electricity.

2.3.2 Various Accessories and Customization

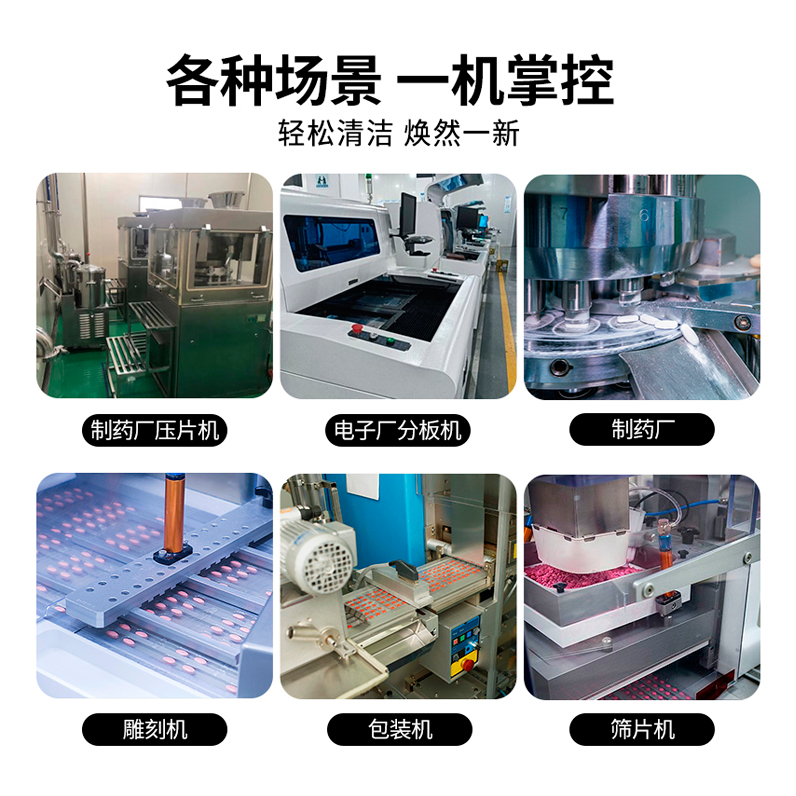

Waidr industrial vacuum cleaners offer a full range of products, including mobile, fixed, grinding support, battery-driven, and vacuum (dust removal) systems, with over 190 models in 18 series. This diverse product range provides various options for different industrial fields and work scenarios. In addition to standard stainless steel structures, they offer various vacuuming and water suction accessories, and the accessory diameters can be customized. For example, in food processing workshops, special small-diameter nozzles that meet food hygiene standards may be needed, and Waidr can provide customized accessories to meet these needs. In machining factories, accessories can be customized based on the size and shape of waste materials generated by the process, making the equipment suitable for different cleaning tasks.

Pressure loss refers to the reduction in pressure as air passes through an industrial vacuum cleaner and its related systems (such as pipelines, filter elements, etc.). In industrial vacuum cleaners, pressure loss mainly consists of two parts: along-the-way pressure loss and local pressure loss. Along-the-way pressure loss is caused by friction between the air and the contact surfaces of the pipeline, while local pressure loss mainly occurs at bends, joints, valves, and sudden changes in the internal structure of the vacuum equipment (such as sudden changes in pipe diameter), where the airflow changes, consuming energy and causing pressure loss.

3.2.1 Pipeline Factors

3.2.1.1 Length and Diameter

The longer the pipeline, the greater the pressure loss. This is because air flowing through the pipeline accumulates friction resistance with the pipe walls as the length increases. For example, in an industrial vacuum cleaner system, when the pipeline length increases from 10 meters to 20 meters, tests show a significant increase in total pressure loss. Additionally, the diameter of the pipeline greatly affects pressure loss; the smaller the diameter, the faster the airflow, leading to increased along-the-way and local pressure loss. For instance, under the same airflow requirements, a pipeline with a diameter of 50mm will have significantly higher pressure loss compared to a pipeline with a diameter of 80mm, as smaller diameters cause more frequent collisions and friction between air molecules and the pipe walls, resulting in greater energy loss.

The roughness of the pipeline also needs to be considered. Smoother pipe walls (such as stainless steel pipes) have a lower friction coefficient compared to rough walls (such as some old cast iron pipes), reducing along-the-way pressure loss. In some old industrial facilities, replacing the pipeline with smoother walls can significantly reduce overall pressure loss.

3.2.1.2 Bends and Branches

Bends are important points of local pressure loss. The angle of the bend (such as common 90° and 45° bends) greatly affects pressure loss; the larger the angle, the more severe the airflow redirection, and the greater the pressure loss. If a vacuum system has multiple 90° bends, compared to using the same number of 45° bends or using curved bends for transitions, the pressure loss will significantly increase. Research data shows that each additional 90° bend can increase local pressure loss by 20-50%, depending on different flow rates, pipe diameters, and other factors.

Pipeline branches also cause pressure loss. When air is distributed to different pipeline directions at a branch, the flow becomes complex, resulting in energy loss. If the branch design is unreasonable, such as uneven resistance in each branch pipeline, it will lead to uneven airflow distribution and greater total pressure loss.

3.2.2 Filter Elements

3.2.2.1 Type and Quantity

Different types of filter elements have significant differences in pressure loss. Paper filter elements generally have lower resistance to air compared to high-efficiency HEPA filters, resulting in lower pressure loss. However, HEPA filters can filter finer particles, meeting higher filtration requirements. For example, in a cleanroom environment in an electronics factory, using HEPA filters, although it increases pressure loss, provides high-quality filtration. Additionally, the number of filter elements affects pressure loss; if multiple filter elements are set in the vacuum cleaner to improve filtration, each filter element will create resistance to airflow, increasing pressure loss. For instance, some industrial vacuum cleaners use relatively loose filter materials for primary filtration of large particles, followed by HEPA filters for fine particle filtration, resulting in increased pressure loss due to the Venturi effect.

3.2.2.2 Cleanliness

The cleanliness of the filter elements significantly affects pressure loss. As the filter elements are used over time, dust and debris gradually accumulate on the surface and inside, blocking the air passages and rapidly increasing resistance, leading to increased pressure loss. For example, in a woodworking workshop, if the filter elements are not cleaned for a long time, the accumulation of wood dust will severely block the filter elements, causing significant pressure loss and reducing the vacuum cleaner’s suction power, affecting the vacuuming effect. The fan may also need to consume more power to maintain airflow, increasing energy consumption.

3.3.1 Airflow and Airspeed

3.3.1.1 Airflow

Airflow is an important factor affecting pressure loss. Generally, the greater the airflow, the greater the pressure loss in the system. This is because higher airflow means more air molecules need to flow quickly through a limited channel, increasing the frequency of interactions and energy loss between the air and the pipeline, filter elements, and other components. For example, an industrial vacuum cleaner operating at low airflow may have a relatively low and stable pressure loss, but increasing the airflow (such as by increasing the fan speed) will result in increased pressure loss.

When designing and operating an industrial vacuum cleaner system, if the airflow exceeds the reasonable design maximum (such as unreasonably increasing airflow to pursue higher cleaning efficiency), it may cause a sharp increase in pressure loss, leading to increased pipeline wear, shortened filter element life, and increased risk of fan failure due to prolonged high-load operation.

3.3.1.2 Airspeed Distribution

Uneven airspeed distribution in the pipeline also causes additional pressure loss. When air flows through the pipeline at uneven speeds (such as due to improper pipeline installation or obstructions in the pipeline), it creates local vortices and turbulence, consuming more energy and increasing pressure loss. In practical applications, optimizing the design of the industrial vacuum cleaner pipeline system to make the airspeed more uniform (such as using tapered pipe diameters and reasonably arranging pipeline routes) can reduce overall pressure loss to some extent.

3.3.2 Operational Duration and Conditions

3.3.2.1 Continuous Operational Duration

As the continuous operational duration of the industrial vacuum cleaner increases, pressure loss tends to gradually increase. This is because the performance of system components may change during prolonged operation. For example, the impeller of the fan may experience some wear during prolonged high-speed rotation, reducing its efficiency in driving air, equivalent to additional pressure loss. Additionally, prolonged operation can exacerbate filter element clogging, as mentioned earlier, increasing pressure loss.

3.3.2.2 Complexity of Working Conditions

The complexity of working conditions significantly affects pressure loss. In environments with a lot of dust, debris, or high temperatures and humidity, these external factors affect the vacuum system's state. For example, in a cement plant, a large amount of cement dust quickly clogs the filter elements; in high-temperature environments, changes in the physical properties of air, such as density and viscosity, increase airflow resistance, leading to increased pressure loss. In relatively clean environments with suitable temperature and humidity, pressure loss increases more slowly.

4.1.1 Meaning and Measurement of Suction Power

Suction power, also known as vacuum degree, is an important performance parameter of industrial vacuum cleaners. It reflects the negative pressure generated at the vacuum inlet during operation, measured in units such as millibars (mbar) or kilopascals (kPa). Suction power is generated by the vacuum fan, and the vacuum cleaner's internal sealing also affects suction power; better sealing results in better suction power because, in a well-sealed system, the fan can more easily draw air from the vacuum inlet, creating greater negative pressure.

4.1.2 Relationship with Pressure Loss

Higher suction power means greater negative pressure, often accompanied by changes in pressure loss. When suction power increases, the air needs to overcome more resistance during the vacuuming process, increasing pressure loss. For example, in scenarios where heavy metal shavings or tightly adhered dust need to be vacuumed, higher suction power is required. However, as suction power increases, the friction loss within the vacuum pipeline and the pressure loss through the filter elements also increase. This is because higher suction power increases airflow speed, intensifying interactions between air and components, and the fan needs to consume more energy to maintain the pressure difference caused by pressure loss, creating a mutually influencing relationship.

4.2.1 Definition and Importance of Power

Power is one of the key factors affecting the suction power and airflow of industrial vacuum cleaners. Power describes the amount of work done by the vacuum cleaner per unit time, directly reflecting the rate of energy consumption, measured in watts (W). It determines the fan's ability to provide wind pressure and airflow. After determining the required suction power and airflow, the motor power can be determined. For example, in large industrial workshops with large cleaning areas and high dust volumes, higher-power industrial vacuum cleaners are typically used to ensure sufficient airflow and wind pressure for cleaning tasks.

4.2.2 Relationship with Pressure Loss

When power increases, the fan speed may increase to provide greater wind pressure or airflow. If the components of an industrial vacuum cleaner system, such as pipelines and filter elements, remain unchanged, increasing power to increase wind pressure and airflow will accelerate airflow in the system, leading to increased pressure loss. Faster airflow increases friction between air and components, and local pressure loss at bends and joints also increases due to higher speed and energy. However, if system components are improved to accommodate higher power output (such as increasing pipe diameter and optimizing filter performance), pressure loss can be mitigated to some extent. Overall, increasing power without reasonable system adjustments often leads to increased pressure loss.

4.3.1 Role of Airflow

Airflow refers to the amount of air the vacuum cleaner draws in per minute, usually measured in cubic meters per minute (m³/min). Higher airflow means more air is drawn in per unit time, carrying away more dust and debris, improving cleaning efficiency. Under sufficient suction power, higher airflow results in better cleaning performance. For example, in textile factories, high airflow helps quickly remove lint and fibers, enhancing cleaning speed and effectiveness.

4.3.2 Relationship with Pressure Loss

Airflow directly affects pressure loss. Similar to water flow in a pipe, higher airflow causes a large volume of air to flow quickly through the pipeline system, increasing friction and collisions between air and components, leading to higher pressure loss. When designing and selecting industrial vacuum cleaners, if a high-airflow model is chosen without matching larger-diameter pipelines, the high airflow in relatively narrow channels will cause a sharp increase in pressure loss, affecting overall system performance. Conversely, lower airflow results in lower pressure loss in the same system.

4.4.1 Meaning of Dust Bin Capacity

Dust bin capacity refers to the total volume of dust, debris, and other waste that the vacuum cleaner's dust bag or collection bin can hold. Larger dust bin capacity reduces the frequency of emptying the bin, increasing the vacuum cleaner's continuous working time and efficiency. This is particularly suitable for industrial environments with high dust generation, such as cement plants and mines.

4.4.2 Relationship with Pressure Loss

Although dust bin capacity may not seem directly related to pressure loss, it does have some impact during operation. For example, when the dust bin is nearly full, the dust particles inside affect airflow within the bin, increasing resistance for air exiting the bin and entering the fan, leading to slightly increased pressure loss. Additionally, if the dust bin capacity is too small, frequent emptying is required, and each restart of the vacuum cleaner requires re-establishing a stable airflow state, causing fluctuations in pressure loss and making it difficult to maintain a stable vacuum pressure environment.